Auto Optical Fastener Inspection Machine

High-Speed Automated Inspection for Micro Screws and Precision Fasteners

Inspecting micro fasteners at production speed presents serious quality control challenges. Small defects in screws and rivet contacts can lead to assembly failures, product recalls, and costly rework. The ACV-16041 Auto Optical Fastener Inspection Machine provides a fully automated, high-speed inspection solution designed specifically for micro fasteners used in electronics and precision manufacturing.

Built for non-stop inspection, the ACV-16041 delivers consistent, accurate quality control at speeds up to 1,000 parts per minute, helping manufacturers reduce defects while maintaining production efficiency.

The Challenge of Inspecting Micro Fasteners at Production Speed

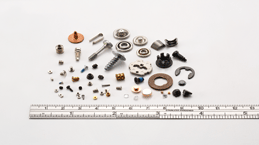

Micro fasteners used in electronics and 3C applications demand extreme precision. As fastener sizes decrease, defects become harder to detect and manual inspection becomes unreliable. Burrs in recesses, thread defects, head cracks, and dimensional inconsistencies often go unnoticed during high-volume production.

Manual inspection methods struggle to keep up with modern manufacturing speeds. Inconsistent results, operator fatigue, and limited defect visibility increase the risk of defective parts reaching assembly lines. For manufacturers producing thousands of micro screws per minute, even a small defect rate can result in significant quality and cost issues.

Automated optical inspection solves these challenges by providing continuous, repeatable inspection without slowing production. High-speed vision systems detect defects consistently, ensuring every fastener meets strict quality standards before reaching the next stage of manufacturing.

Automated Optical Inspection Solution for Micro Screws and Fasteners

The ACV-16041 Auto Optical Fastener Inspection Machine is designed to eliminate the limitations of manual inspection while keeping pace with high-volume production environments. Using a high-magnification CCD vision system and precision lighting, the machine performs continuous, non-stop inspection of micro fasteners without interrupting workflow.

This automated inspection system accurately evaluates fasteners ranging from M0.6 to M4, making it ideal for electronics and micro-component manufacturing. By inspecting up to 1,000 parts per minute, the ACV-16041 allows manufacturers to maintain throughput while achieving consistent and repeatable quality results.

Automatic feeding, inspection, and sorting ensure that only conforming parts move forward in production. Defective components are identified and separated immediately, reducing rework, scrap, and downstream quality issues.

What the ACV-16041 Can Inspect

Fastener Defects and Quality Criteria Detected

The ACV-16041 performs comprehensive optical inspection across multiple fastener characteristics. Its vision system evaluates both dimensional accuracy and surface quality to ensure compliance with strict manufacturing standards.

Inspection criteria include:

- Head width and head height

- Pinhole depth and recess shape

- Burrs in recess areas

- Spiral thread defects

- Thread inner diameter and outer diameter

- Neck length and shank verticality

- Overall screw length

- First thread condition

- Drunk thread detection

- Head cracks and surface damage

- Plating defects

- Insert nut thread defects

- Dimensional inconsistencies

By inspecting these criteria simultaneously, the ACV-16041 provides reliable quality control for micro screws and fasteners used in precision applications.

Applications and Industries

Designed for Precision Electronics and Micro-Component Manufacturing

The ACV-16041 Auto Optical Fastener Inspection Machine is engineered for industries that require high-accuracy inspection of small, high-volume fasteners. Its ability to inspect micro screws at production speed makes it well suited for electronics and precision manufacturing environments where consistency and reliability matter.

Common applications include inspection of fasteners used in:

- Mobile phone and handheld device assembly

- Notebook and laptop manufacturing

- Digital camera and optical device production

- MP3, PDA, and compact electronic products

- Semiconductor and micro-component assemblies

These applications demand strict quality control due to tight tolerances and the impact even minor fastener defects can have on final product performance.

Key Features and Benefits

High-Speed Optical Inspection Without Production Bottlenecks

The ACV-16041 combines advanced vision technology with a stable mechanical platform to deliver reliable inspection results at high speed. Its non-stop inspection capability supports continuous production while maintaining consistent quality standards.

Key features and benefits include:

- High-speed inspection up to 1,000 parts per minute, supporting high-volume manufacturing without slowing output

- Dual CCD camera vision system with precision lighting for accurate defect detection

- Telecentric lens technology that provides consistent measurements regardless of part position

- Automatic feeding and sorting system that separates good and NG parts in real time

- User-friendly operation and maintenance, reducing training time and operator dependency

- Industrial-grade components, including an industrial PC and Mitsubishi servo motor, designed for long-term reliability

These features help manufacturers reduce inspection variability, improve yield, and maintain consistent quality across production runs.

Technical Specifications

| Series No. | ACV-16041 |

| Appling Component | Micro screw, special micro parts, semiconductor parts |

| Diameter of Component | M0.6-M4 standard |

| Length of Component | 25mm |

| Head Width | 25mm |

| No. of CCD | 2 CCD |

| Vision System | Highly magnified CCD camera / light source sets |

| Software | Accuvision Pro-V II version 2.5 |

| Supply and Output | Feeding bowl / linear track / sorting bins (Good/NG) |

| Speed | 600~1000 pcs/min |

| Power | AC 220 – 240V / 50Hz |

| Mainframe | Industrial computer, MITSUBISHI servo motor, Industrial CCD, Telecentric lens |

| Machine Spec. | 1065mmL×860mmW×1,855mmH |

Why Choose AQVision

AQVision specializes in optical inspection solutions designed for real-world manufacturing challenges. Rather than offering generic inspection equipment, AQVision focuses on systems that address specific production requirements, including micro fastener inspection for electronics and precision components.

Manufacturers choose AQVision for:

- Expertise in automated optical inspection and machine vision systems

- Solutions tailored to high-speed, high-precision production environments

- Support for electronics, semiconductor, and micro-component manufacturing

- Local service capabilities combined with national reach

A consultative approach focused on solving inspection challenges, not just selling equipment